Customers of our dealers often wonder what to consider when installing LED work lights. We understand that correctly connecting and adjusting your work lighting is a specialized art. That's why we're happy to tell you what to look out for and why a homogeneous (LED) lighting setup is invaluable on your tractor. Working safely begins with good visibility.

A non-homogeneously lit work environment brings unsafe situations

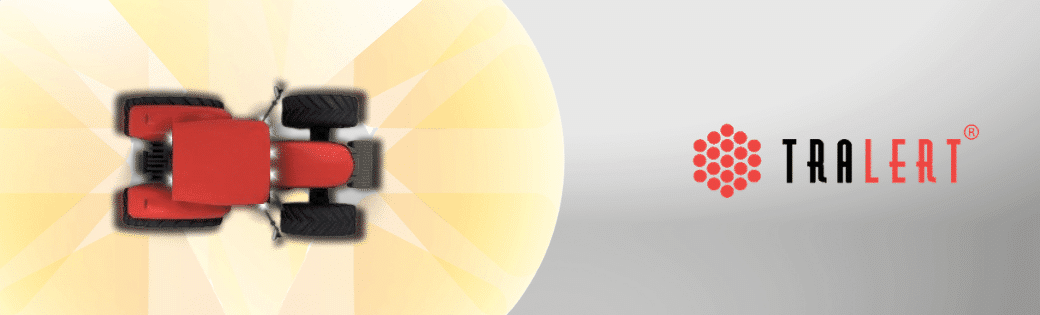

In the following image, you can see an example where the installation of LED work lights has been done poorly compared to a well-lit workspace. The LED lighting on the tractor lacks proper adjustment or equipment. This results in a poorly lit work environment. You can recognize a poorly lit work environment by the individual light beams that appear uncoordinated among the light rays in the work area. These uncoordinated dark spots are visible in the comparison photo below (photo 1). The result of this setup of work lights creates a sharp, abrupt light-dark boundary on the sides of the tractor and dark spots at the front of your tractor. As a result, you may not recognize hazards in time. So, a truly safe work environment is not present.

An example where the coordinated arrangement LED work lights is correct

Met goed afgestelde homogene verlichting is dit natuurlijk een ander verhaal. Door het werklicht rondom je trekker gelijkmatig te verdelen, zorg je ervoor dat deze donkere, abrupte donker/licht spots er niet meer zijn. De focus van het licht uit de werklamp ligt in het midden en de zachtere delen van de lichtstraal kruisen elkaar op het juiste moment. Hierdoor ontstaat een gelijkmatig helder zicht in alle richtingen rondom jouw trekker. Dit maakt je als bestuurder instaat gevaren eerder te herkennen en hier accurater op te reageren. Wél zo prettig voor jou en je collega’s. In de bovenstaande afbeelding (foto 2) is een voorbeeld opgenomen van een juist verlichte werkomgeving dankzij een juiste montage van LED werklampen.

The main factors to consider when installing LED work lights

There are four essential components in creating a homogeneously lit work environment. These components can be divided into:

The reflector of the LED work light

At TRALERT®, we attach great importance to the reflector of the work light. In the development of work lights, extra attention is paid to the desired light pattern in the context of our customers' applications. We ensure that the reflector surfaces that direct the light to the work area are optimally and correctly reflective. For example, we use TIR and RFT lens technologies. The application of the reflector lens can vary from one work light to another. For instance, there are lenses designed specifically for "wide beam" and lenses designed for long-distance illumination. To provide your tractor with a homogeneously illuminated work environment in close proximity, we recommend a wide-beam work light. If you're specifically looking for spotlights, you might consider an LED bar or our smaller spotlights.

The mounting height of the LED work lights | Advice: at least two meters

Homogeneous illumination on your tractor is only possible with a high installation. That's why TRALERT® advises maintaining a minimum height of 2 meters when mounting LED work lamps. In most cases, work lights are therefore attached to the roof of your tractor. This is the location that meets the 2m requirement to achieve the correct lighting angle for creating a homogeneously illuminated workspace.

Positioning for mounting an LED worklight

Because the advice is to mount a work lamp at a height of two meters, the roof of your tractor is a common mounting location. Other common locations for work lights are the fender and the mirror bracket. These are often smaller TRALERT® work lamp models used to illuminate a specific function. When mounting on the roof, inspect your tractor's roof to discover if there are prepared locations for TRALERT® work lamps. Often, our LED work lamps can be mounted in the places where existing halogen lighting is located. If this is not the case, you can always seek advice from a TRALERT® specialist. If you want to highlight specific areas, you can always mount additional LED work lamps on the mirror bracket or the fender.

The set inclination angle of the working light

We advise you to pay close attention to the proper adjustment of the LED work lamps to achieve a homogeneous illuminated work area. Only well-adjusted work lamps lead to an optimal light pattern. Make sure to adjust the angle so that you no longer have 'blind spots' between the lamps. light beams got. If the current equipment of work lights on your tractor is insufficient, consider the heavy-duty TRALERT® lighting for even more light output.

TRALERT's range of work lamps®

At TRALERT®, as mentioned earlier, you'll find a wide range of LED vehicle lighting. You can easily order all work lights directly from stock through our dealer network. The extensive range includes standard LED work lights as well as professional heavy-duty LED work lights, from wide-beam LED work lights to spotlights. Because we understand that you may need work lights for both your tractor and your car, we've equipped our LED work lights with a wide voltage range from 9-30v to 9-110v (high voltage). Additionally, we've simplified the connection process by using various common and safe connections. These include the... Deutsch-connector, Super Seal en AMP In short, a solution for almost every question. If you haven't been able to find what you're looking for or if you have more questions about the installation of LED work lights, let us know, and we'll see if we can assist you further.

Ordering your LED work lights from TRALERT®

Ordering an LED work light from TRALERT is easy and fast. As a TRALERT partner, you can easily order work lighting online through the dealer portal. If you need more technical information before you are sure about your order, do not hesitate to contact our product specialists. They are happy to assist you in creating a homogeneously lit work environment.