A trouble-free 24V lighting system is essential for safety and reliability in vehicle construction. Poor wiring, incorrect connections, or the wrong components can lead to faulty lighting, error messages, and malfunctions.

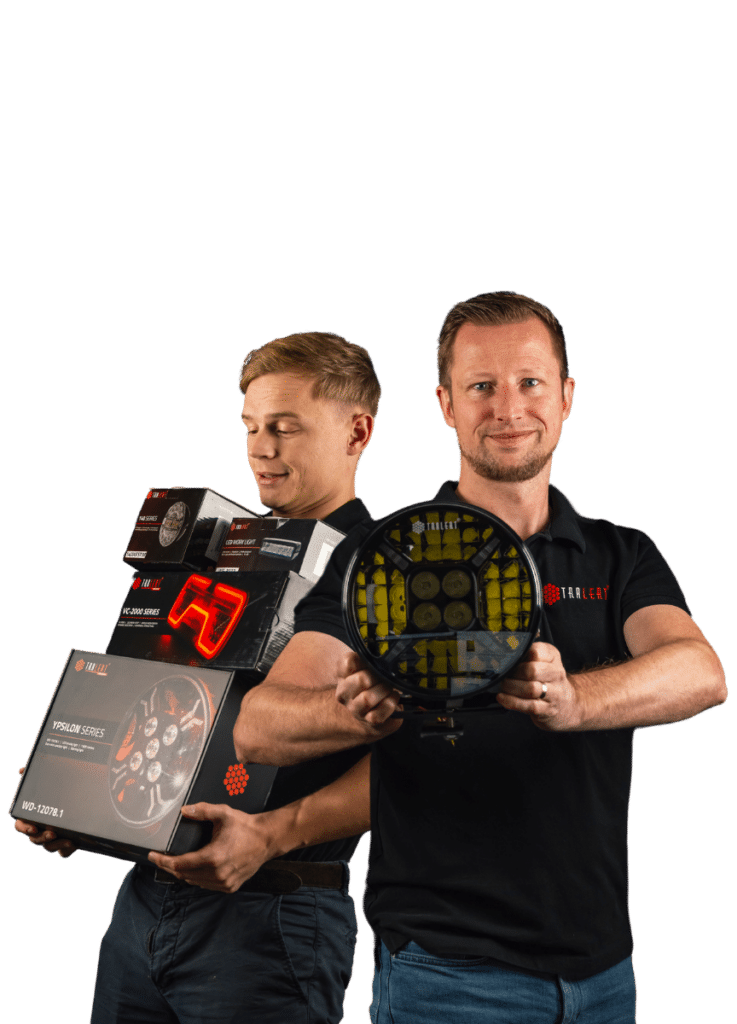

TRALERT® helpt professionals met kennis en oplossingen om deze problemen te voorkomen. In deze gids ontdek je welke onderdelen cruciaal zijn en hoe je jouw voertuigverlichting optimaal installeert.

In this guide, we cover:

- The essential components of a well-functioning lighting system.

- And we refer to in-depth articles on specific issues and solutions.

Common malfunctions: troubleshooting and prevention

A lighting system can experience malfunctions. Below, we discuss common issues and how to prevent them.

Causes and solutions

- Loose connections and contact issues.

- Cable wear due to vibrations.

- Short circuit due to moisture infiltration.

A well-maintained vehicle lighting system prevents unexpected failures and extends the lifespan of the lighting. Regular maintenance and choosing smart solutions such as plug-and-play systems help minimize malfunctions.

Preventive maintenance: Periodically check connectors, wiring harnesses, and plug connections for wear and corrosion. Replace damaged parts in time to prevent failures.

Plug-and-play lighting systems: These systems make replacing lighting easier and reduce installation errors, improving reliability.

Regular inspections: By setting fixed inspection intervals, small issues can be detected and resolved early before they lead to major malfunctions.

Want to learn more about the causes of malfunctions and how to prevent them? Check out our troubleshooting guide for 24V vehicle lighting.

Cable thickness and quality: why is this important?

A well-designed wiring harness distributes power efficiently and prevents malfunctions. Especially in 24V systems, where longer cable runs are common, proper wiring is essential.

A wiring harness with the correct cable thickness prevents voltage drop and overheating, which is essential for a reliable lighting system. Additionally, a water- and dustproof finish is crucial to prevent moisture and corrosion, especially for vehicles operating under harsh conditions.

Finally, plug-and-play connections simplify installation and ensure that components can be replaced quickly and without errors.

The connector choice for 24V lighting

The type of connector you need depends on the application and the specific requirements of the vehicle. Here, we discuss the most commonly used options.

Deutsch-connector

The Deutsch connector is robust and suitable for harsh conditions. This type is widely used for LED bars and spotlights and is resistant to dust, water, and vibrations.

Advantages of the Deutsch connector:

- Reliable in extreme conditions

- Easy to install without special tools

- Widely applicable in truck and trailer lighting

Superseal connector

The Superseal connector is often used in trucks and trailers due to its water- and dustproof properties. This makes it ideal for applications where extra protection is required.

Advantages of the Superseal connector:

- Prevents malfunctions caused by moisture and dirt

- Compact and easy to install

- Ensures a safe and stable power connection

Why always choose ECE-certified lighting?

For vehicles in participating UNECE countries, it is mandatory to use ECE-certified lighting. Without the proper certification, you risk fines and rejection during inspections.

Common standards:

ECE R65 – Warning beacons and signal lighting

- ECE R65 – Zwaailampen en signaalverlichting

- ECE R48 – Montagevoorschriften

Read all about ECE regulations and vehicle lighting.

CAN-bus issues and solutions

By choosing CAN-bus compatible lighting, proper wiring, and high-quality connectors, you can prevent communication issues within the system. Regular diagnostic checks also help detect and resolve malfunctions in time.

How does a CAN-bus control box work?

In a conventional electrical system, lighting and other components are controlled directly via physical switches and relays. In a CAN-bus system, an ECU (Electronic Control Unit) sends digital signals through a single data cable to all connected components. This reduces the number of wires in a vehicle and ensures faster and more efficient communication.

Time-saving plug & play systems

Waarom moeilijk doen als het makkelijk kan? Plug & play systemen besparen installatietijd en verminderen fouten, waardoor storingen worden voorkomen.

Advantages:

- Quick installation without soldering or crimping

- Less chance of incorrect wiring

- Easy to replace in case of defects

Discover how TRALERT® plug & play lighting systems make the job easier.

Frequently Asked Questions:

What is the difference between a Deutsch connector and a Superseal connector?

Deutsch connectors are designed for extreme conditions and are widely used in heavy-duty vehicles. Superseal connectors are more compact and provide better protection against moisture and dust.

How do I know which wiring harness I need?

This depends on the voltage (12V or 24V), the required functions, and the vehicle’s connection options.

Can I combine 12V and 24V components?

No, this can damage the electronic components. Always use components that are suitable for the same voltage.

The right choice of plugs, connectors, and wiring harnesses is essential for a properly functioning electrical system in truck and trailer lighting. By considering the correct voltage, required connections, and working conditions, you can prevent malfunctions and extend the lifespan of vehicle lighting.

Want to learn more about vehicle lighting and wiring? Check out our knowledge base with extensive technical articles. Or become a partner of TRALERT®.