Lighting malfunctions can be costly in terms of time and money. They also impact vehicle safety and reliability. For workshops, issues such as flickering lights, moisture infiltration, and CAN-bus failures are common challenges.

In this blog, you will learn how to:

- How to address malfunctions: flickering, moisture issues, and CAN-bus errors

- Perform a quick diagnosis: practical steps for efficient testing of cables and systems.

- More about plug & play solutions: complete systems that make your work easier.

Types of wiring harness failures

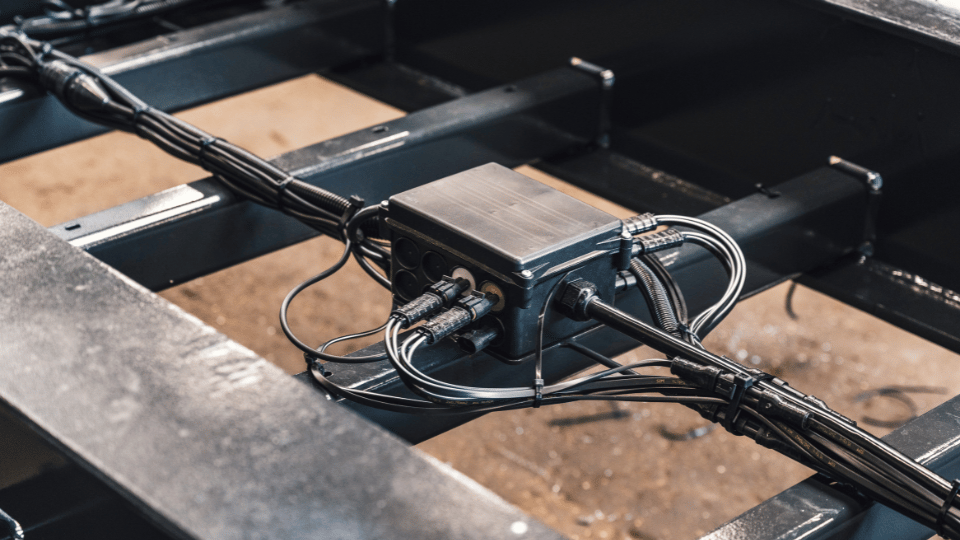

Wiring harnesses are the backbone of any lighting system. Common causes of malfunctions include:

- Poor connections: Corrosion or loose connectors disrupt the power supply.

- Wear and tear: Vibrations and temperature fluctuations damage insulation and wiring.

- Overload: A cable that is too thin leads to voltage drop and overheating.

Step-by-step diagnosis of wiring harness issues

- Visual inspection: Check connectors for corrosion or loose connections. Look for damaged cable insulation.

- Test the voltage: Use a multimeter to measure the voltage at each endpoint. A deviation indicates a cable or connection issue.

- Check the resistance: Measure the resistance in the cable. A value higher than 0.5 ohms indicates wear or corrosion.

- Check the grounding: Use a voltage meter to test if the grounding is functioning correctly.

Prevention tips:

- Always choose the correct cable thickness. For a 10-amp lamp with a 3-meter cable length, a cable with a cross-section of 1.5 mm² is ideal. For longer cables (>5 meters), at least 2.5 mm² is required.

- Protect wiring harnesses from mechanical stress with cable ducts or additional insulation layers.

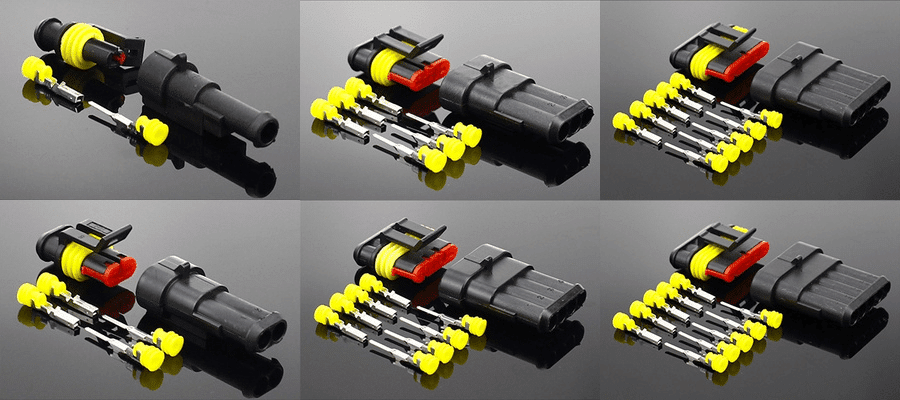

- Use waterproof connectors such as Superseal connectors to prevent moisture and corrosion.

- Moisture infiltration is a common cause of failures. Therefore, choose lighting with a high IP rating for maximum protection against moisture and dirt infiltration. For performance in the harshest conditions with heavy dirt and moisture exposure, a product with IP69K is the best choice.

Other problems you may encounter with semi-trailer lighting:

Flickering lighting

- Cause: Poor grounding, voltage fluctuations, or incompatible CAN-bus systems.

- Solution: Check if the lighting is compatible with the electrical system and test the wiring for loose connections.

Overheating

- Cause: Poor ventilation or excessive load on the system.

- Solution: Ensure adequate heat dissipation and use wiring with the correct cable thickness.

Color changes

- Cause: LED aging, poor power supply, or faulty drivers.

- Solution: Check the power supply and replace LEDs that no longer meet the original color values.

Moisture issues

- Cause: Poor sealing of connectors or damaged cable insulation.

- Solution: Use high-quality connectors (IP67 or higher) and protect the cables with heat shrink tubing if necessary.

Lighting function issues

- Cause: Broken lamps, faulty wiring, or malfunctions in the electrical system.

- Solution: Use a multimeter to check if voltage is present at the correct points. Inspect the wiring for damage and replace defective connectors. If the issue lies within the system, a CAN-bus control box can help transmit the correct signals and prevent malfunctions.

The Importance of ECE and CE Certified Products

When you work with products that comply with ECE standards, you not only ensure that your lighting is legally permitted but also minimize the risk of technical failures. TRALERT®'s lighting products meet these standards.

Dit zorgt ervoor dat bedrading en connectoren bestand zijn tegen de eisen van ECE R10 (elektromagnetische compatibiliteit).

Saving time with lighting kits

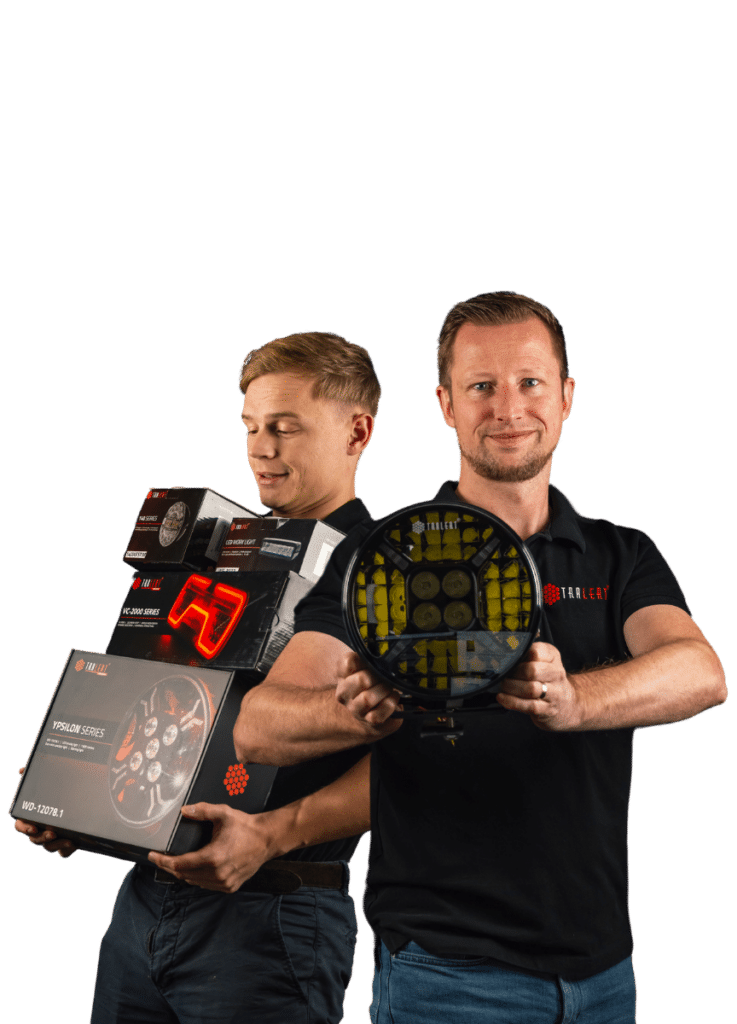

TRALERT® offers not only custom solutions but also a range of ready-to-use lighting sets. Ideal for standard trailers. Also perfect for replacing old lighting. The TRALERT® lighting sets are complete lighting solutions that include everything needed to equip your vehicle with safe and high-quality lighting. These sets have been carefully assembled by TRALERT®'s LED specialists, with special attention to regulations, ease of installation, and product quality.

Custom lighting solutions for 24-volt systems such as heavy transport & trailer construction

At TRALERT®, we are ready to support you with innovative solutions for any lighting system. Our plug & play systems, robust wiring harnesses, and superseal connectors are designed to make installations easier and trouble-free.

Take advantage of:

- Technical support: from design to installation, we think along with you.

- Access to the dealer portal: for loyalty-based pricing, quotes, and insight into your orders.

Explore the possibilities to become a partner of TRALERT®.