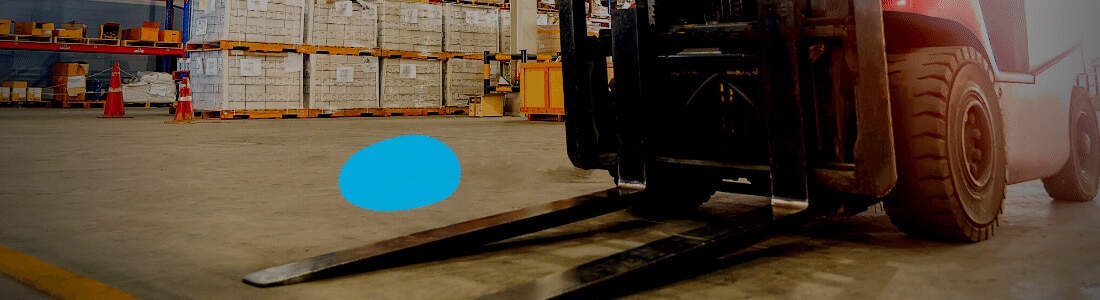

Working safely with a forklift truck in a warehouse. It sounds easy, but sometimes things can get hectic. For example, when there are many deliveries to be made in a short period of time. Or when new stock is delivered in large numbers. When things get hectic, it's nice to have technology you can count on, as well as being able to rely on your colleagues. The lift truck is a smart device in terms of safety. For example, trucks nowadays can automatically slow down on bends and display blue or red arrows on the ground when reversing, so colleagues know you're coming. In addition to these, there are many other methods or tools that make it possible to work safely with a forklift truck.

1. Increasing forklift safety through the use of parking brakes

To enhance safety when working with the lift truck, a parking brake or hand brake is built into every lift truck. The purpose of this brake is to prevent the forklift truck from rolling when it is on sloping ground. The parking brake has been developed so that it can be used even when the forklift is not moving. Use it to your advantage! Use the parking brake not only when you put the forklift away at the end of the day but also when you get off the machine. This is how you make safe working with a forklift truck possible.

2. Use a safety belt when working with a forklift truck

To legally comply with forklift safety laws, drivers are required to use a safety belt. In addition, safety restraints or an Access Control system provide even more safety. The Access Control system ensures that the truck does not release the brake until the safety belt is clicked on.

3. Safe working with the forklift truck by means of LED lighting

To legally comply with forklift safety laws, drivers are required to use a safety belt. In addition, safety restraints or an Access Control system provide even more safety. The Access Control system ensures that the truck does not release the brake until the safety belt is clicked on.

Blue spot lamp

By mounting colored lights on your forklift, such as the Blue Spot work light, a clear blue spot shines on the warehouse floor. This serves as a reminder to your colleagues in the warehouse that a forklift is nearby. The purpose of this blue forklift light is to alert your colleagues on the shop floor. When driving in reverse, as a driver, you have limited visibility of your surroundings. You are focused on performing your tasks. The use of safety lighting greatly enhances safety in the warehouse.

LED worklights on a forklift truck

In addition to warning lights for your colleagues, proper driving lights are also crucial. When forklifts are used at night or in dark places, it is highly recommended to equip the forklift with a good set of LED work lights to work safely with the forklift. These work lights can be mounted on the front, top, or rear of the forklift. Even when you need to drive the forklift on public roads, it is necessary to equip the forklift with lighting. This ensures you are always prepared for any situation.

Forklift safety with lighting for public roads

When you take a forklift onto the public highway, the forklift is a means of transport and in addition to the Working Conditions Decree the Road Traffic Regulations also apply. When driving on public roads it is necessary to have at least the following set of lights on the forklift:

- Two headlights (not working lights) at the front;

- Direction indicators at both front and rear;

- Alarm lights;

- Two rear lights and two brake lights.

It is also important that the rear of the vehicle is fitted with a red reflective triangle, better known to us as a triangular reflector. If your forklift is longer than six metres, it must be fitted with extra direction indicators and orange retro-reflectors.

4. Create a forklift-friendly layout

To work safely with a forklift truck, there must be enough space between the racking. This allows for forklift trucks to manoeuvre carefully, but at a fast pace, through the various aisles of the warehouse. When you have a full warehouse, the width of the racking makes it easy to manoeuvre a forklift safely.

5. Safe operation of the forklift truck with the load diagram

To enable safe working with a lift truck, a load diagram is fitted on every lift truck. The load diagram contains important information about the working load, the load centre distance, the lifting capacity and the lifting height. This information helps the driver of the lift truck to determine whether it is safe and responsible to transport a certain weight.

6. Ensure the involvement of staff

Although there are many tools to help make forklift operations safe, people are the most important factor. It's people who make up the rules, and hopefully follow them. In our blog on blue LED lights you can read that there are on average 126 serious accidents involving forklift trucks each year. In order to prevent this, it is very important to create involvement and support among the staff. As mentioned before, it can be difficult to keep an overview in a busy warehouse. In addition to the above, it would also be a good idea to put up various signs and signals in the warehouse so that everyone is reminded of the rules around forklift safety.

7. Have your forklift truck checked regularly

To ensure your lift truck meets all safety standards, it is important to keep it in good and safe condition. A periodic inspection by a certified mechanic can't do any harm. Apart from the fact that working safely with a certified forklift truck goes better, it is also mandatory to have the forklift inspected periodically due to the Dutch Working Conditions Act.

One part of this inspection is the use of lighting on your forklift truck. Do you have questions about which lighting is best to use on your forklift? Then feel free to contact our technical specialists. Would you like to discover our entire range of LED lighting for yourself? Then take a look at our dealer portal.